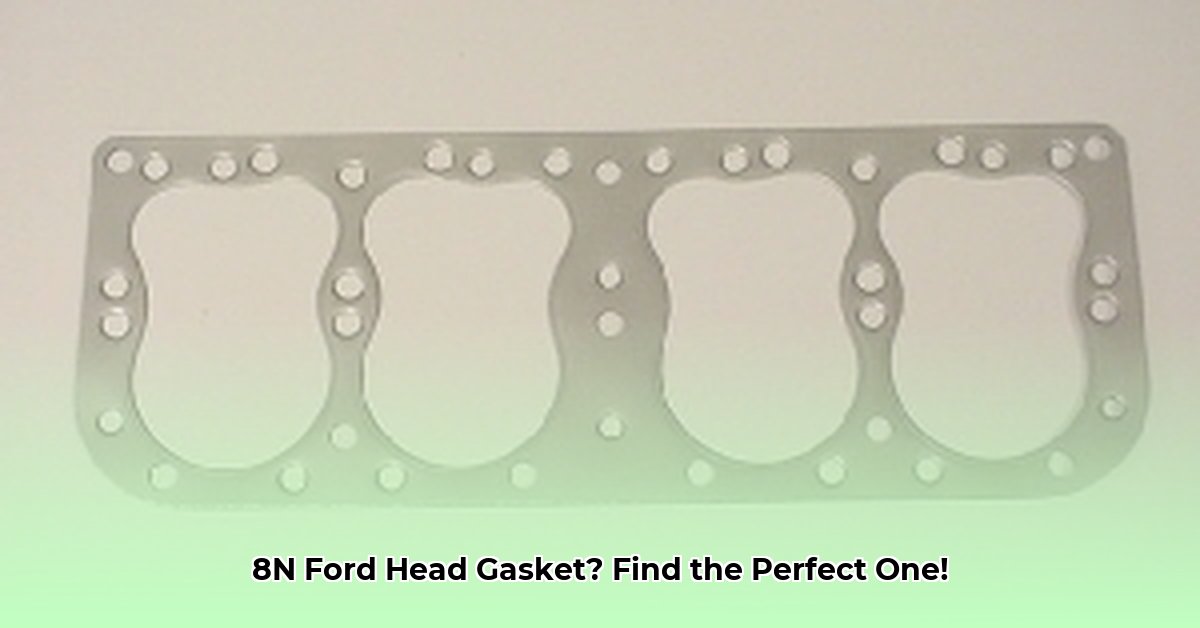

Finding the perfect head gasket for your Ford 8N tractor can feel like navigating a maze, but this comprehensive guide will provide the clarity you need. We'll cover everything from identifying the correct part to installation and preventative maintenance, ensuring your tractor runs smoothly for years to come. This guide is for both experienced mechanics and those new to tractor repair, offering a blend of practical advice and detailed instructions. For even more 8N resources, check out this helpful Ford 8N website.

Identifying the Correct Gasket: Precision is Paramount

The first step to a successful repair is identifying the precise head gasket your 8N requires. This isn't a one-size-fits-all situation; variations exist depending on your tractor's engine and build year. Your tractor's serial number and engine type are crucial. Without them, you're essentially guessing, potentially leading to costly mistakes. Common part numbers include 8N6051A and 9N6781, but others exist. Referring to your owner's manual is vital.

A wrong gasket can lead to leaks and engine damage, making this step incredibly important. The following table provides estimated pricing and material options, but remember these are subject to change depending on the vendor and current market conditions.

| Part Number | Description | Estimated Price Range (USD) | Material Options | Notes |

|---|---|---|---|---|

| 8N6051A | Common Head Gasket | $15 - $40 | Metal, Composite | Widely available, often a good starting point |

| 9N6781 | Alternative Head Gasket | $12 - $35 | Metal, Composite | May be suitable for certain 8N variations |

| Others | Various other gaskets | Varies widely | Varies | Consult your tractor's manual for specifics |

Always cross-reference part numbers with multiple reputable suppliers before purchasing. Don't solely rely on price; gasket quality directly impacts engine performance and longevity.

Choosing the Right Material: Durability vs. Cost

Head gaskets come in various materials, each with its advantages and disadvantages. The most common are metal and composite (non-metal) gaskets.

Metal Gaskets: These offer superior durability and sealing, especially under high pressure. They are typically more expensive and require precise installation. However, their longevity can translate to long-term cost savings. A rhetorical question: Is the higher upfront cost of a metal gasket justified by its increased durability and the potential to avoid costly future repairs?

Composite Gaskets: These are generally cheaper and easier to install, making them a good option for DIYers. However, they may not be as durable as metal gaskets and may not withstand consistently high temperatures or pressures as effectively.

The optimal choice depends on your budget and the intensity of your tractor's use. For standard use, a high-quality composite gasket is often sufficient. However, for demanding applications or high-performance modifications, a metal gasket may be preferable.

Selecting a Reliable Supplier: Due Diligence is Key

Choosing a reputable supplier is crucial. A faulty gasket can lead to engine damage. Consider these factors:

- Online Reviews: Check independent reviews on platforms like Amazon, eBay, and dedicated vintage tractor forums. Look for consistent positive feedback regarding quality, shipping, and customer service.

- Return Policy: A clear and accommodating return policy protects you in case of defects or incorrect ordering.

- Shipping Costs and Times: Compare shipping costs and estimated delivery times. Faster shipping can be beneficial during urgent repairs.

Prioritize reliability over price. A slightly more expensive gasket from a trusted supplier is a better investment than a cheap gasket that leads to major engine issues.

Step-by-Step Installation Guide: A Detailed Approach

Replacing a head gasket is a complex task requiring mechanical skills and proper tools. If you lack experience, consulting a qualified mechanic is strongly recommended. Improper installation can cause catastrophic engine damage. The following is a general outline; always consult your tractor's service manual for precise instructions and torque specifications.

Step 1: Preparation: Thoroughly clean the engine block and cylinder head mating surfaces. Remove all traces of the old gasket. This is crucial for a proper seal. Step 2: Inspection: Carefully inspect the cylinder head and engine block for warping or damage. Any imperfections could prevent a proper seal. Step 3: Gasket Placement: Position the new gasket precisely on the engine block, ensuring correct alignment. Step 4: Head Installation: Install the cylinder head, tightening the bolts sequentially according to manufacturer's specifications using a torque wrench. Step 5: Retorquing: After initial tightening, allow the engine to cool and retorque the bolts to ensure a consistent seal.

(Note: High-quality images and videos illustrating each step would greatly enhance this guide.)

Troubleshooting and Preventative Maintenance: Long-Term Care

Even with proper installation, problems can occur. Recurring leaks may indicate incorrect installation, a damaged head, or a defective gasket. Premature failure might result from overheating.

Regular maintenance is crucial:

- Monitor Engine Temperature: Keep a close eye on engine temperature to prevent overheating.

- Check Coolant Levels: Regularly check coolant levels to ensure proper cooling system function.

- Address Leaks Promptly: Deal with any leaks immediately to prevent escalating problems.

Preventative maintenance is far more cost-effective than major repairs.

Conclusion: A Well-Maintained Ford 8N is a Joy to Operate

Replacing a Ford 8N head gasket demands precision and attention to detail. Choosing the right gasket, a reliable supplier, and following proper installation procedures are key to a successful repair. Remember to consult your tractor's service manual for specific instructions and torque values. If uncertainty arises, seek professional help. A well-maintained Ford 8N will reward you with years of reliable service.